Discover why millions of Dip-Tech printed automotive and transportation glass panels are already in use in a wide range of vehicles around the world.With a comprehensive automotive solution package, our machinery and special set of inks meet the automotive industry’s most demanding standards and requirements for intensive mass production capacities.

Automotive

Digital Printing Solutions

Dedicated serial production solution for automotive, transportation & industrial digital printing

Ferro is the world’s leading provider of automotive and transportation enamels. It offers a wide range of specially formulated ceramic automotive glass enamels and silver conductive pastes, suitable for tempering, lamination, sag or press bending and pre-firing. These enamels are specially designed to meet decorative specifications and to prevent degradation and delamination of vehicle glass adhesive from UV-light radiation, as required by automotive OEM and after-market industry specifications.

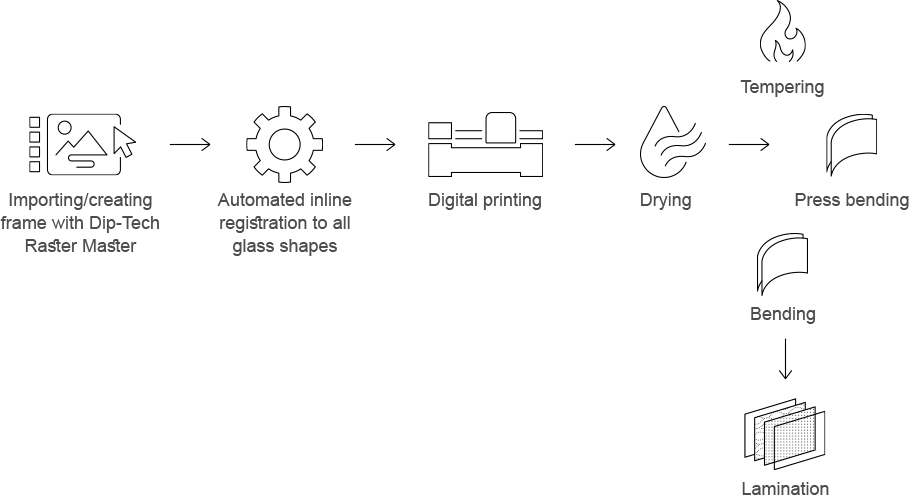

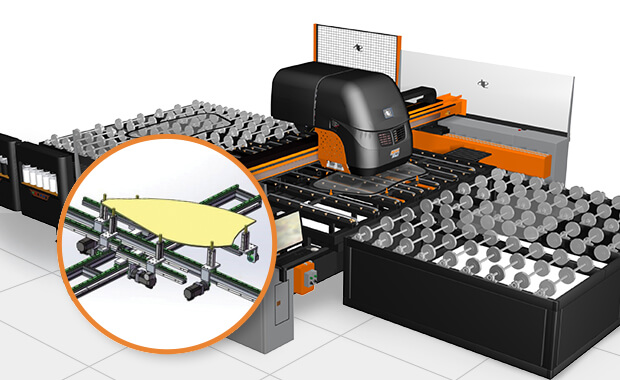

The choice between screen printing and digital printing is not a zero-sum game. Both offer excellent quality. In fact, digital and screen printing are often best used in tandem, allowing glass processors to shift between the formats according to need, to better utilize screen capacity, and fully maximize ROI. To enhance the learning process and ramp-up business, Dip-Tech provides you with the end-to-end support you need in order to deliver outstanding printed glass products and increase both your potential and market share. Introducing Nera-V, Dip-Tech’s dedicated serial production solution for automotive, transportation and industrial digital printing. With the backing of Ferro’s automotive glass experience and know-how, it is the new generation of Dip-Tech’s automotive solution, following millions of automotive and transportation glasses, printed over the past 13 years with Dip-Tech printers and inks. Dip-Tech’s industrial-level Nera-V printer is the most adv anced digital ceramic glass printing solution for printing automotive and repeatable patterns. It offers turbo-charged throughput, superb quality, and a competitive ROI compared to screen printing in larger batches. Fully inline and automated, it delivers cost-efficient, high-quality automotive glass printing, with quick and accurate registration on any glass shape – all at serial production speed.

Build your business with a full solution by Ferro & Dip-Tech

Glass Types

ROOF GLASS

Automotive Black Digital Ink (72 hours test) or Automotive Anti-Stick Black Digital Ink

- UV filtration

- Hard coating compatibility

WINDSHIELD

Automotive Black Digital Ink (72 hours test)

- Automotive Anti-Stick Black Digital Ink for press bending

- Rasters

- Frames

- Logos

- Barcodes

Automotive Conductive Silver Digital Ink

- Camera

- Radar

- Wiper demisters

- Sensors

Automotive Silver Hide Digital Ink

- For silver-hiding applications

BACKLIGHT

Automotive Anti-Stick Black Digital Ink for press bending (72 hours test)

- Frames

- Logos

- Barcodes

Automotive Conductive Silver Digital Ink

- Fine lines

- Bus bars

- Wiper demisters

- Sensors

- Defrost system

Automotive Silver Hide Digital Ink

- For silver-hiding applications

DOOR GLASS

Automotive Black Digital Ink (72 hours test) or Automotive Anti-Stick Black Digital Ink

- Frames

- Logos

- Barcodes

QUARTER GLASS

Automotive Black Digital Ink (72 hours test) or Automotive Anti-Stick Black Digital Ink

- Frames

- Logos

- Barcodes

Automotive Raster Master

An innovative Dip-Tech tool that assists to create gradient raster pattern for automotive / transportation black frame drawings.The tool can automatically create raster grid to all frame designs; provides seamless raster arrangement in corners, curves and special fill area on the CAD; replaces tedious corrections and completions of rasters in the current process; Interfaces with AutoCAD.

Dynamic Index system

Dip-Tech VX-3 is designed for the unique demands of the specialty transportation industry. It includes an inline automatic indexing system that enables to register a wide variety of glasses shapes and sizes, allowing for a fast and user-friendly setup.

Make digital glass printing for serial production your advantage

Cost savings

- Save screen purchase costs

- More space in the factory

- Zero screen preparation and reduced post-print cleaning

- Reduced labor, with a single operator

Efficiency

- Rejection of screen setup time

- Move between jobs with just a few mouse clicks

- Fully automated and in-line with your production line

- High print quality and accuracy at high speeds

Flexibility

- Suitable for varied processes – Firing, tempering or bending

- Easy file preparation and customization, easy sampling

- Full control over wet layer thickness, with easy customization

- Enables variable data printing – For batch number or QR code

Improved printed product

- Lower enamel surface roughness – Better glass strength

- Minimal printer setup enables easy adding of a second color

- Short lead time for sampling

- Inks - digital versions of industry-compliant, proven Ferro enamels

Recommended Applications

Agricultural, construction & specialty vehicles

The special transportation industry has a unique set of glass demands. Whether it’s laminated glass for rough and tough terrain, or windshield repair you need Dip-Tech digital glass printing offers the dedicated serial production solution for your agriculture, construction and specialty vehicle demands. read more

Automotive replacement glass

Whether you need windshield replacement, car window repair, or general car glass, Dip-Tech’s dedicated serial production solution for automotive is the answer for you. Fully automated and inline, Dip-Tech offers the most advanced digital ceramic glass printers for automatic indexing of glass registration, with no manual operation required. read more

Bulletproof & protective vehicles glass

With our expertise in digital glass printing, Dip-Tech is proud to supply the dedicated serial production solution needed for the bullet-resistant glass required of civilian and military applications. Effectively serving as a glass protector, our digitally printed laminated glass can be used for windscreen replacement, windshield crack repair, or any functionality where auto glass is needed. read more

Buses & RV

The special transportation industry has a unique set of glass demands. Whether it’s laminated glass for rough and tough terrain, or windshield repair you need Dip-Tech digital glass printing offers the dedicated serial production solution for your agriculture, construction and specialty vehicle demands. read more

Marine glazing & yacht interiors

At Dip-Tech, we’re proud to offer a truly innovative, high-tech solution dedicated to marine glass and windows. Both attractive and functional, Dip-Tech digitally printed glass is perfect for multiple purposes, from replacement glass to glass repairs. read more

Rail transport

With increased urbanization and environmental consciousness, the passenger transport sector is a growing market around the world. In fact, rail transport, buses, and coaches are one of the fastest growing glass markets. read more