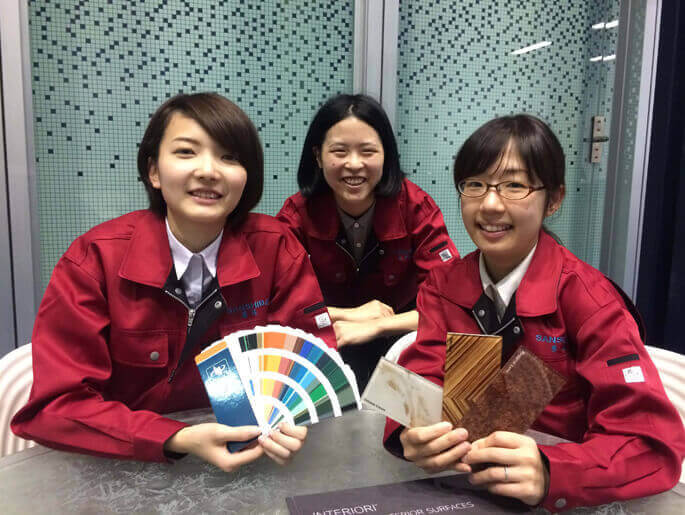

With its innovative technologies, Dip-Tech has been providing cutting-edge solutions for architecture, interior design, automotive and appliances for over a decade.Together with Ferro and Dip-Tech’s unique 360° support, global reach and industry-leading knowledge, you are closer than ever to achieving digital glass printing excellence.

Products

DIGITAL CERAMIC PRINTERS

Rediscover digital glass printing with Dip-Tech’s innovative solution for the architectural flat glass industry.

High throughput for all applications at the highest resolution.

The GPi series provides a superior platform for a wide range of exterior and interior architecture applications, automotive replacement, bullet proofing and marine glazing.

Introducing the new generation in digital printing on automotive glass. Dip-Tech VX-3 combines an automatic dynamic index system for positioning various glass shapes together with Dip-Tech’s innovative SmartDrop Technology, resulting in a fast, efficient, and flexible printing platform.

DIGITAL CERAMIC INKS

SOFTWARE TOOLS

CMiX - SPECTRUM R Color Guide

An easy-to-use, web-based swatch book for Dip-Tech’s new and improved SPECTRUM R digital ink series.

read more

DXP

Dip-Tech DXP 3 glass design and graphics platform enables advanced image processing for digital ceramic glass printing.

read more

Raster Master - File preparation for shaped glass made easy

An innovative tool by Dip-Tech that helps create gradient raster patterns for automotive / transportation black frames.

read more